Four Factors For Determining Tool Tethers - Toolbox Talks

Toolbox Talks are intended to facilitate worksite health and safety conversations. Click here to download talking points on the four factors of determining tool tethers to prevent dropped objects.

With 52,000 injuries, 278 fatalities and hundreds of millions of dollars lost annually, the time for Dropped Object Prevention is now.

In our last Toolbox Talk, we went over phase one: how to create ANSI/ISEA 121-compliant attachment points for tools that don’t inherently have them. But that’s only half the battle—what good is an attachment point if you don’t use the proper tool tether to secure it while working at height?

Between loop ends vs. carabiners, retractable vs. non-retractable, length, weight capacity and more, there’s a lot out there when it comes to tool tethers and—more specifically—tool lanyards. Teaching workers about the benefits and use cases of various tool tether types is crucial for increasing the safety of working at height on your worksite.

In this Toolbox Talk, we’ll review the four factors for determining the appropriate solution to employ in your tool tethering systems.

FACTOR #1: TOOL LANYARD WEIGHT CAPACITY

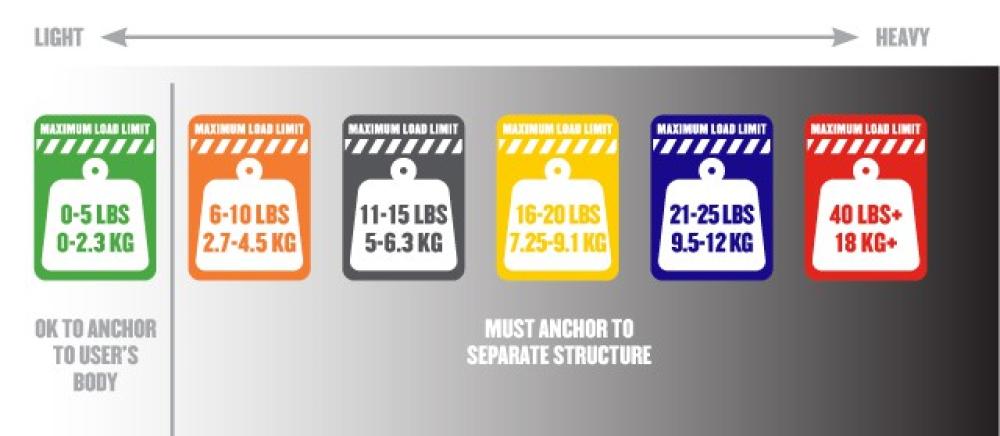

Tool lanyards come in a variety of weight capacities, so knowing the weight of the tool you need to tether is necessary for ensuring the utmost safety while working at height.

Ergodyne Tool Lanyards are categorized in the following capacity ranges:

FACTOR #2: TOOL LANYARD CONNECTOR TYPE

There are two primary tool lanyard connection types: loop and carabiner. To determine the proper connector for your tool tethering system, consider the location of the tool’s attachment point, the intended anchor location and how the anchored tool is being used.

Loop vs. Carabiner

Loop ends fit through a variety of tools and anchor points, but do not connect or exchange quickly.

Carabiner ends are not compatible with as many attachment points as loops are, but they enable quicker connection and exchange.

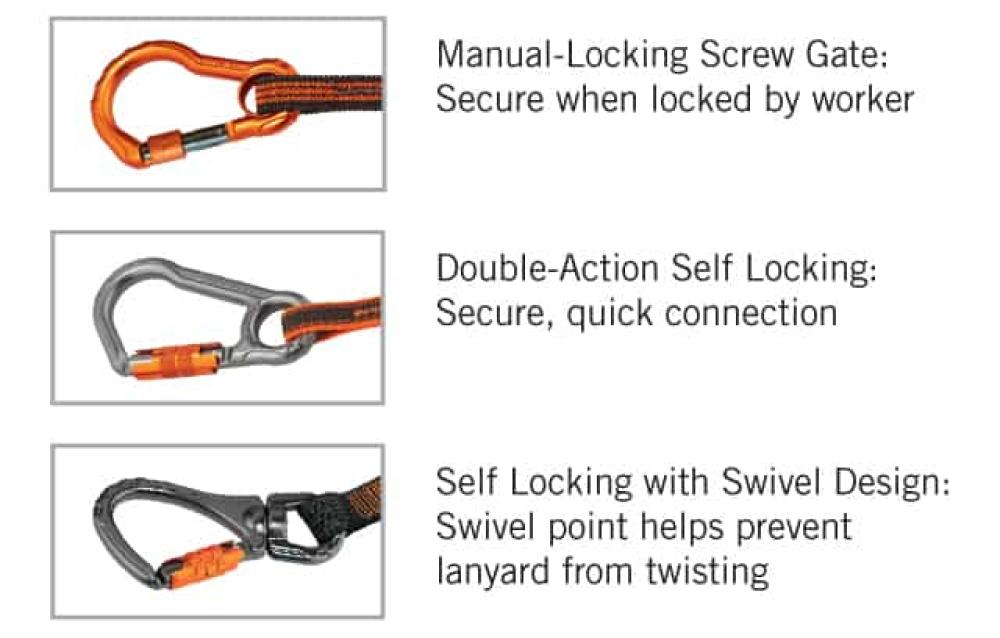

Security of Carabiner

It’s important to note that not all carabiners are created equal and, to ensure maximum effectiveness, workers should also consider elements of an auto-locking carabiner vs. a manual-locking screw-gate carabiner.

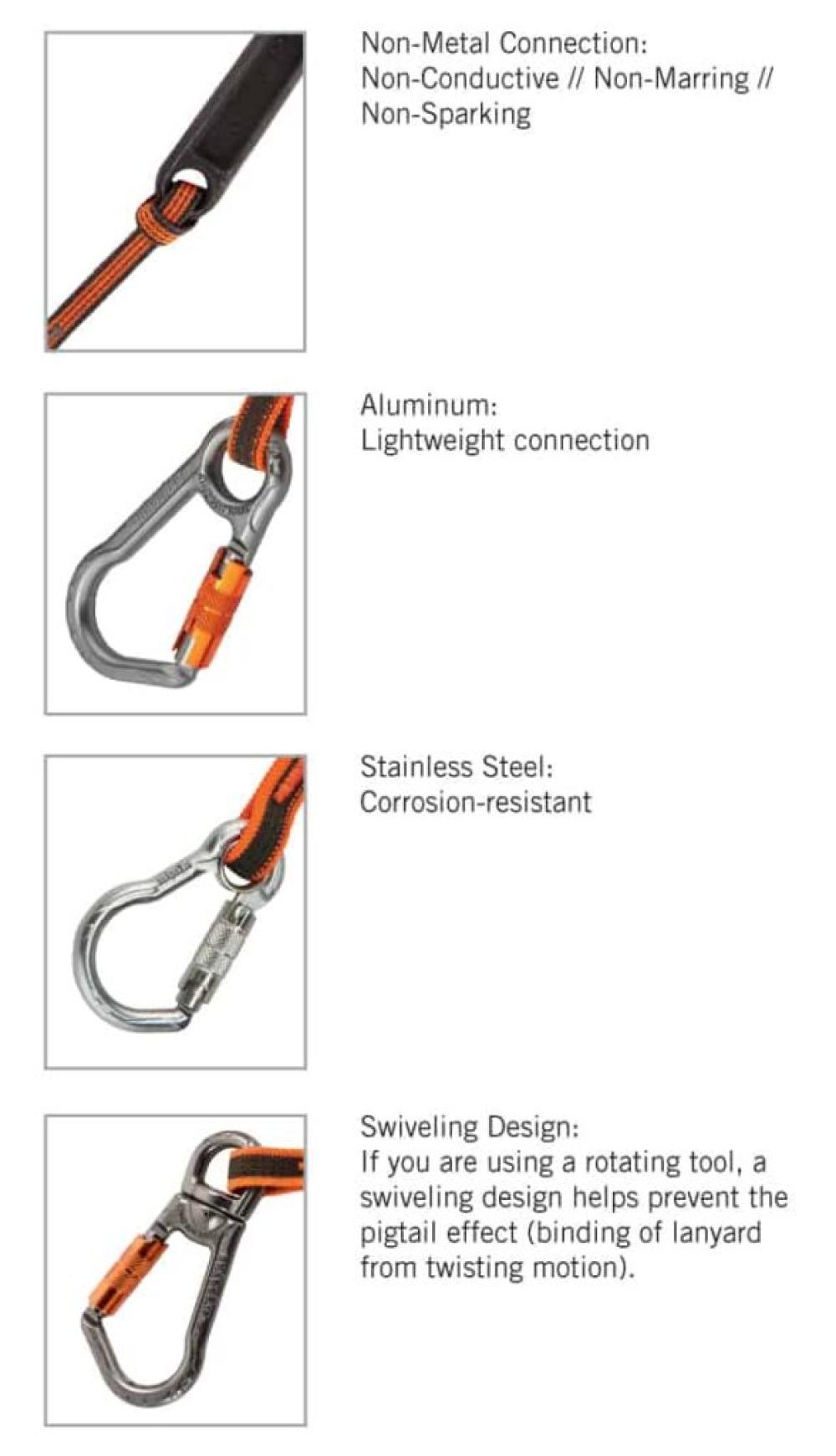

Connector Material

The optimal connector material is heavily dependent on your work conditions. Some environments are more suitable to non-metal, some to corrosion-resistant and others require lighter weight solutions.

FACTOR #3: TOOL LANYARD LENGTH - CLEARANCE, REACH AND SNAG HAZARD

Tool lanyard length should be determined by three factors: clearance, reach and snag hazard.

- Clearance: how much space is needed between anchoring location and nearest sensitive surface, object or person below

- Reach: length of the user’s reach to ensure lanyard expands far enough

- Snag Hazard: if working in confined space or application where lanyards with excess space may become get caught up, a short lanyard or retractable lanyard may be needed

Standard tool lanyard lengths:

- Wrist: 7.5” // 19cm

- Coil: 7.5”-48” // 19cm-123cm

- Retractable: 11”-48” // 28cm-123cm

- Stretch: 35”-48” // 89cm-123cm

FACTOR #4: ADDITIONAL TOOL TETHER OPTIONS

Outside of the primary considerations, there are other unique features that may be beneficial to certain tasks while working at height.

Modular Quick Connect

Quick connecting buckle allows for exchange of multiple tools to a single lanyard.

Tool Tails (additional accessory) are available for this system.

Twin Leg

Twin leg lanyards allow two tools to be connected or 100% tie off for one tool when transferring tools from point A to point B (e.g., from a hoist bucket to a structure).

TALK TO YOUR CREW

What good is all this knowledge if you don’t share it? Taking a few minutes before a shift to educate your crew on how to safely tether tools for working at heights is a simple yet effective measure for reducing risk and boosting productivity.

Share this PDF with your crew to educate them on creating tool attachment points

LEARN EVEN MORE

Determining the right tool tether for the job is a crucial step in the Dropped Object Prevention, but it’s not the only one. For a deeper dive into tool tethering and the statistics around workplace safety at-heights, check out our Dropped Objects Safety Prevention Guide.