What Should I Wear? Safety Glasses vs. Safety Goggles vs. Face Shields

Look around.

The eyes have plenty of enemies in the workplace.

Glass shards, cement chips and saw dust. Chemical and solvent splashes. Caustic vapors. Solder sparks. Nails and staples literally shot from a gun.

Even the sun 91 million miles away (UV rays).

And yet OSHA’s eye and face protection standard 1926.102 is annually one of the top ten most frequently violated every year, to the tune of about $6 million in proposed penalties for all industries. We don’t take chances with our heads, our hearing, our hands, feet and lungs (respirators) like we do with our eyes. OSHA standards for those types of personal protective equipment never make the top ten list of shame.

Considering eye protection seems as straightforward as PPE gets, those numbers are particularly frustrating. But is it really that simple? After all, you have options. Plenty of them. Safety glasses, safety goggles and face shields. You also have prescription safety glasses for those who need them (or over-the-glasses options) and convertible safety glasses that become goggles (aka “spoggles”).

So what to wear, and when?

WHEN SHOULD SAFETY GLASSES BE WORN?

Safety glasses once looked like something worn by Buddy Holly, with thick black frames and square lenses. Due to ANSI Z87 rigid design requirements, those glasses and similar nerdy styles were standard long after the day the music died. A new age dawned in the early 1980s when OSHA in its wisdom issued a “variance” permitting wraparound lenses. Fast forward and many safety glasses now look like consumer sunglasses, sleek, contoured, colorful, many with the wraparound design, some with no frames, many meeting the latest ANSI eye protection standard, Z87.1+.

About that “+” in the ANSI standard. Z87.1+ markings on eye protection indicate the eyewear—safety glasses, goggles and face shields—offers protective-plus, having passed more stringent high-velocity impact testing. How’s that? The standard’s high mass impact test drops a 1-pound pointed weight from at least four feet onto eyewear mounted to a head form. The high velocity test fires a steel ball at 102 MPH for safety glasses, 250 MPH for safety goggles. To earn the “+” mark, no break or fracture can appear on the frame or lens.

Safety glasses protect against head-on and side impact. Lens size and shape (some designs with lenses angled back toward the face are closer fitting) are major factors. Safety glasses are likely the first thought when it comes eye protection. Executives and visitors walking the shop floor wear safety specs. So do many factory, warehouse and construction workers not in close proximity to a specific hazard.

Skullerz safety glasses are lightweight, easy to put on and off, and comfortable. Some models feature flex-fit temples that reduce pressure and headaches caused by tight-fitting frames; soft grip side arms that stay put on your face; adjustable temples that shift up or down and lock into place to fit a variety of face sizes. Wraparound lenses give a full field of vision. Impact-resistance is a must, along with enhanced anti-fog performance, scratch-resistance and UV protection.

Safety glasses are your base eye protection. Are they all the protection you need? Well, what work are you doing? Safety glasses are generally effective against projectiles, less so against fine particles and splash risks due to a gap between the lenses and the face.

WHEN SHOULD SAFETY GOGGLES BE WORN?

Safety goggles provide a seal between the lens and frame and the face. This seal keeps contaminants from reaching the eyes. Safety goggles are an upgrade in protection, though some workers consider them less comfortable due to the tight face seal. Some models have a soft frame gasket that limits eye exposure to dust, debris and liquid splashes while giving a comfortable fit over long periods.

The seal can cause fogging, so look for models with anti-fog technology. Vented frame and non-vented frame models are available, depending on your needs. Non-vented goggles offer complete protection from fine dust, particles, droplets and splashes. Vented frames allow the comfort of air flow and improved anti-fog performance. Impact protection, scratch-resistance and UV protection are musts. Some models come with removable lens, elastic or neoprene straps to secure safety helmets, and over-the-glasses designs that allow the goggles to be worn over prescription safety glasses.

Safety goggles protect against more hazards than safety glasses, such as chemical cleaning, hazardous chemical use, high dust environments, brick/stone/concrete masonry work, metal grinding and turning, spray painting and powered woodworking tools. Goggles are the transparent barrier between high velocity debris and blunt objects, splashing liquids and airborne droplets, airborne dust particles and caustic vapors.

WHEN SHOULD FACE SHIELDS BE WORN?

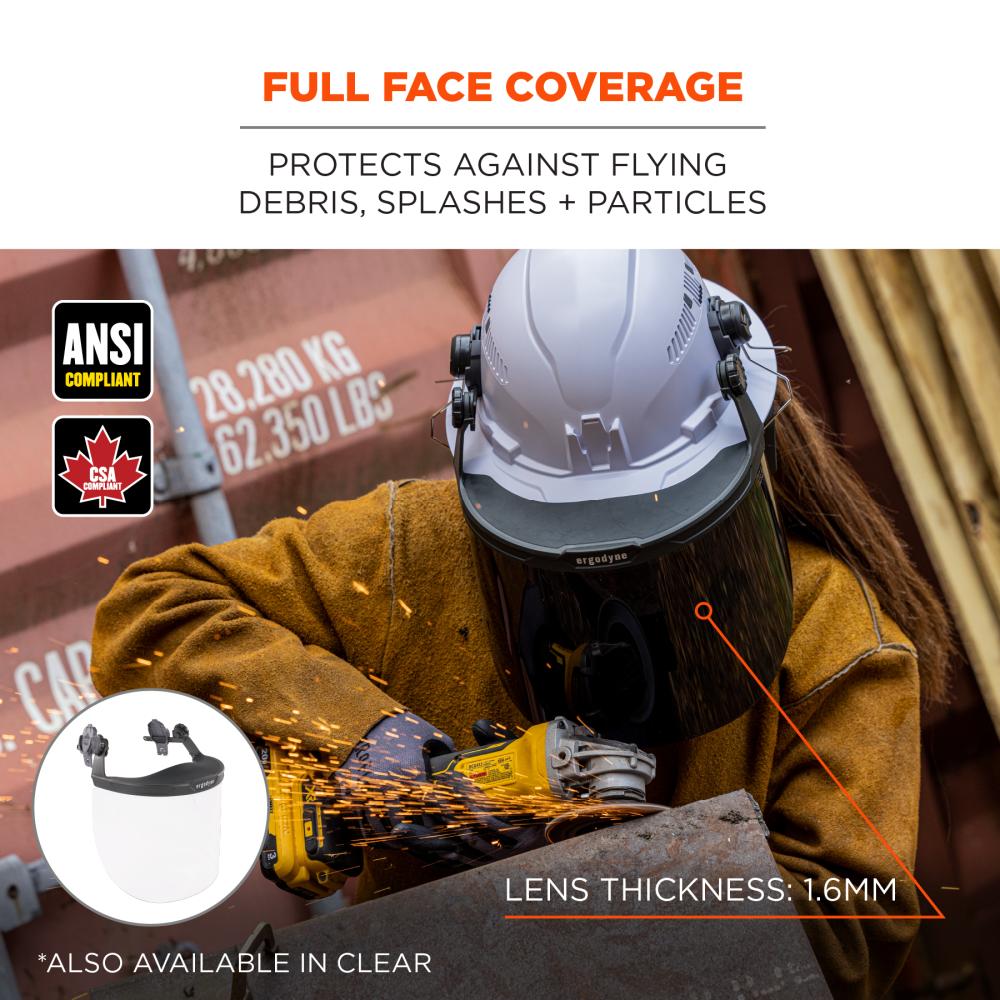

Face shields give you the broadest eye and face protection—it is a shield after all. And it affords max coverage from your forehead to below your chin, covering the nose and mouth, and extending from cheekbone to cheekbone. Face shields offer full-frontal protection against flying debris, chemical splash, molten metal, explosive power tools including nail guns, arc flash, UV radiation and splattering or splashing of biohazardous fluids. Face shields lack the seal of goggles, rendering them vulnerable to airborne particular hazards and dusts.

Many face shields are designed for hard hat integration, increasing above-the-shoulders protection. These face shields pivot up and down (fully down, mid-way, or fully up) and an adapter pivots forward and backward for a custom fit and field of vision. A soft visor adapter conforms to the hard hat or safety helmet shell to help keep dust and debris out of your face.

Look for face shields that are impact-resistant, meet the ANSI Z87.1+ performance requirements, and provide scratch resistance, anti-fogging treatment and UV protection.

Mesh face shields will not fog up in use and provide protection while permitting airflow for increased comfort. Mesh face shields protect against flying debris such as wood chips during woodcutting and chain sawing, and are good for outdoor applications such as brush clearing and trimming and other landscaping jobs, especially in hot weather. For added protection, pair this face shield with Skullerz Safety Glasses or Sunglasses.

EXPLORE YOUR EYE PROTECTION OPTIONS >>

FAQ

Safety glasses protect your eyes from various workplace hazards, including flying debris, dust, chemicals, and particles. They are designed to provide a barrier against potential eye injuries and help maintain clear vision in potentially dangerous environments.

The "Z87+" stamp on safety glasses indicates that they meet or exceed the ANSI Z87.1 standard. This standard is set by the American National Standards Institute (ANSI) and signifies that the safety glasses have been tested and certified for their ability to provide adequate eye protection in various workplace conditions. Safety glasses with the "Z87+" stamp are designed to withstand impacts, protect against flying debris, and provide reliable eye protection, making them suitable for a wide range of industrial and occupational settings.

Safety glasses should be worn whenever there is a risk of eye injury due to flying debris, dust, chemicals, sharp objects, or any other potential workplace hazards. This includes activities like construction work, woodworking, welding, using power tools, handling chemicals, and working in areas with the potential for eye injuries. It's essential to wear safety glasses to safeguard your eyes in these situations and ensure your overall safety.

Safety goggles should be worn when you need protection against more substantial eye hazards, such as chemical splashes, liquid or caustic substance exposure, fine dust or particles, and potential high-impact risks. They provide a sealed and secure fit around the eyes, offering superior protection in situations where safety glasses may not provide adequate coverage. Industries like chemistry, healthcare, and manufacturing often require the use of safety goggles to ensure complete eye safety.

A face shield should be worn when there is a risk of exposure to potentially harmful substances, such as flying debris, chemical splashes, or infectious agents that can affect not only your eyes but also your face and respiratory system. They are commonly used in healthcare settings, laboratories, welding facilities, and when handling hazardous materials. Face shields provide full facial coverage, making them ideal for situations requiring maximum protection and preventing contamination or injury to the face.

At Ergodyne, our face shields are intended to be worn in general labor settings, such as cutting down a tree, as opposed to being used for healthcare purposes.

OSHA requires the use of safety glasses when there is a risk of eye injury from flying particles, dust, chemicals, or other hazards in the workplace. Specific instances include tasks involving welding, cutting, grinding, using power tools, handling chemicals, and working with materials that can create airborne debris. Employers are responsible for assessing workplace hazards and ensuring that employees wear appropriate safety glasses when necessary to comply with OSHA regulations and protect workers' eye safety.