What Goes Up Shouldn’t Come Down: Falling Objects and Dropped Object Prevention

Whether or not they realize it, fans of the old Looney Tunes understand vertical velocity. How many times did Wile E. Coyote think he’d rigged the perfect rock-and-rope device to squash The Road Runner? Invariably, things went south for the poor prairie wolf, and his panicked look flashed on-screen before he vanished from sight as his own concoction dragged him down.

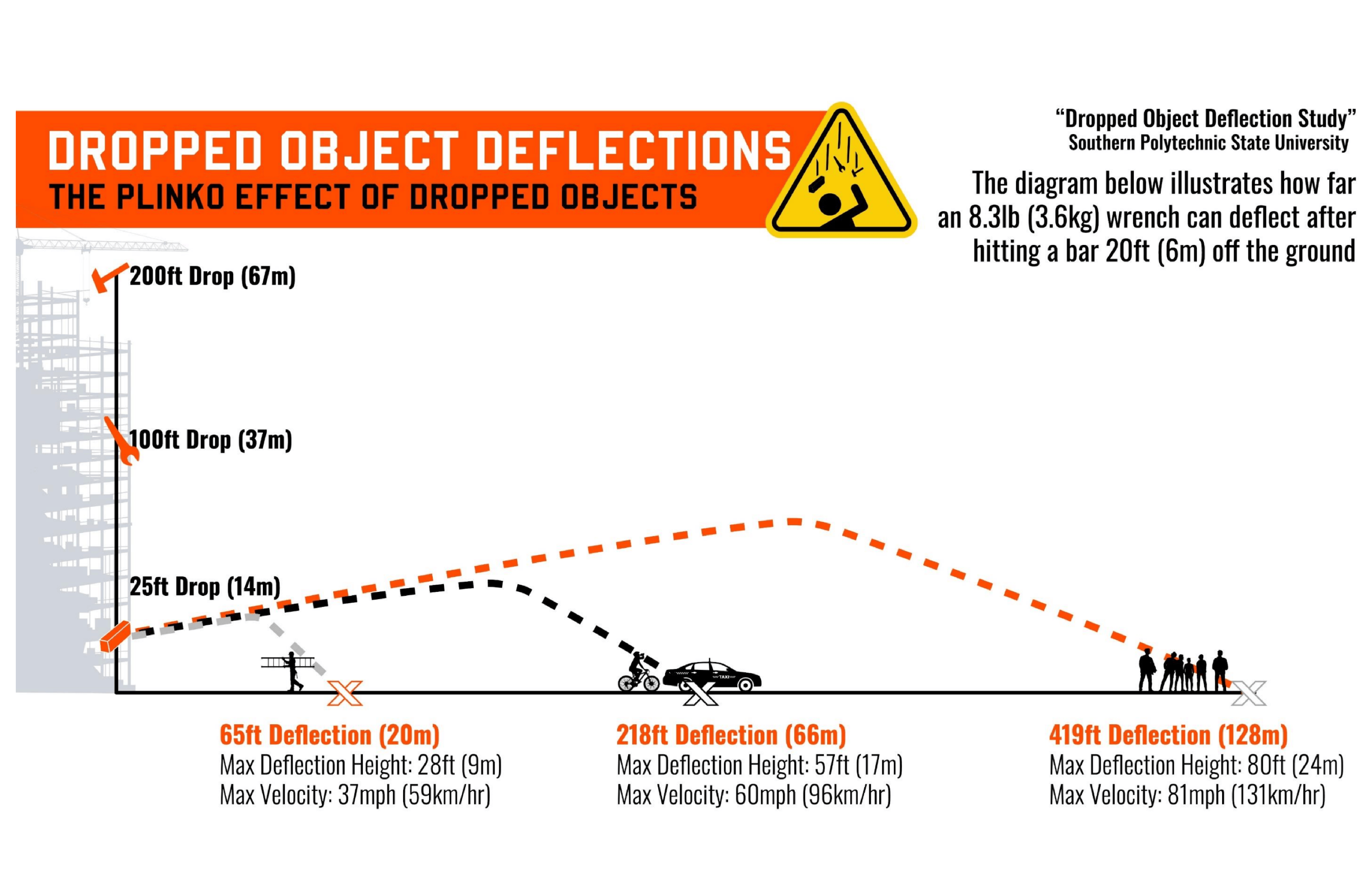

Thanks to gravity, falling objects gain speed the longer and farther they have to fall. While this may be funny in cartoons, it’s scary for those who work at high heights. It’s this same principle of physics that can turn a harmless torque wrench into a plummeting projectile streaking down from the sky.

Fortunately, there are several solutions designed to improve worker safety by reducing the forces required to slow that moving object back to zero.

The Tool Stops Here: Shock Loads and Shock Force

If a falling object decelerates rapidly against the ground, pavement, or another solid surface, that object usually gets bent or broken. We can use stretchy or bendy materials to try and absorb some of that energy, but a better approach is to prevent that impact in the first place.

An accepted way to keep tools and other gear secure at heights is by tethering. Essentially a leash, the following have been used as tethers:

- Cables

- Chains

- Ropes

- Webbing

But those objects can't eliminate gravity – or improve deceleration. A falling object “caught” by a tether is subject to “shock” loads, instead of impact. This shock is force transmitted instantly to the whole system: the tool, its attachment point, the tether itself, and the tether’s anchor. Each of these components needs to be considered.

Normally, shock load is not a concern for a hardened steel tool, like a wrench or a pry bar. But a power tool or sensitive instrument is a different story. Internal components may break free or collide. Those lessons were learned by studying worker fall protection: a rigid, static lifeline might keep a body from hitting the ground, but could be the indirect cause of whiplash or severe internal injuries.

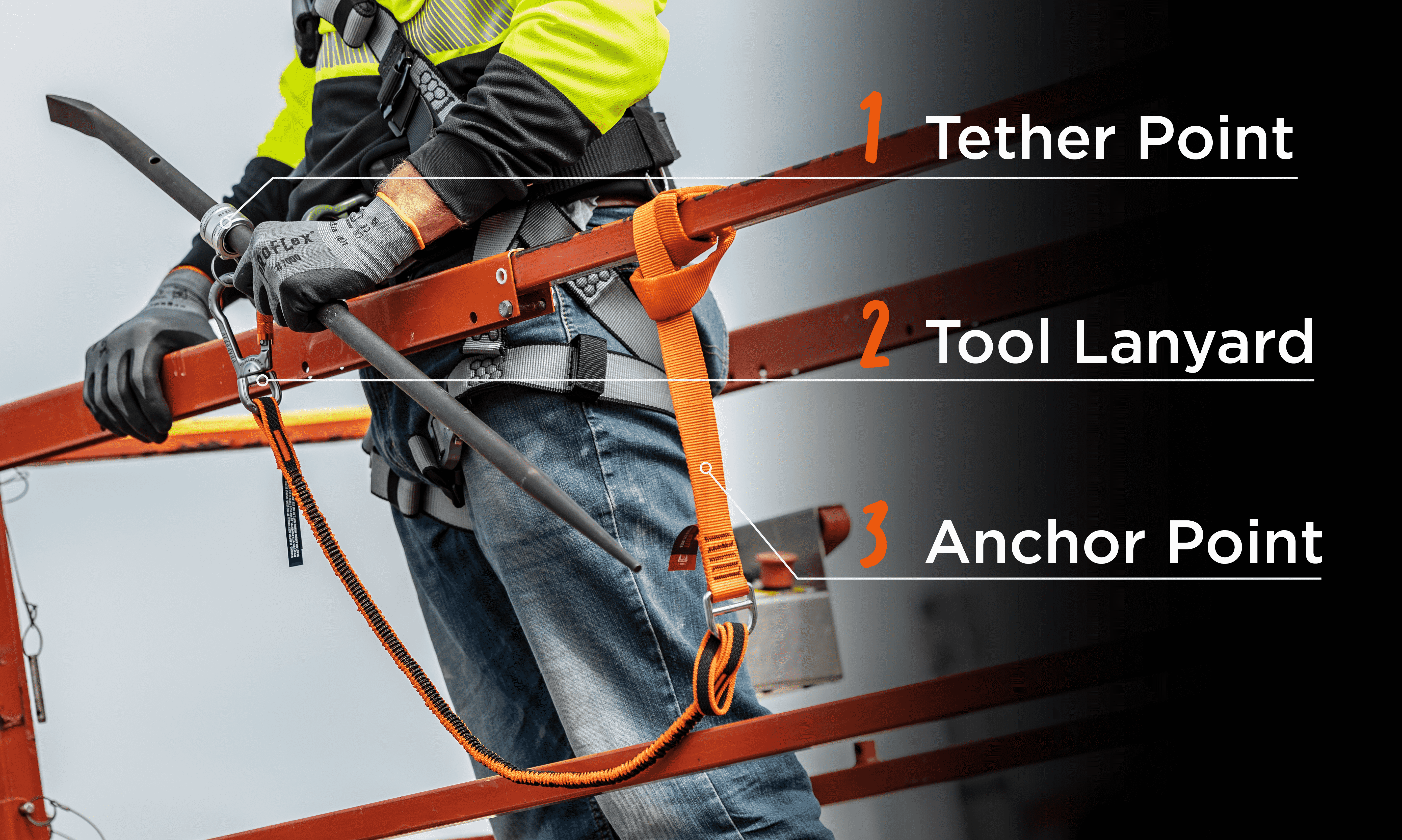

Making Connections: The Anchor Point

Similarly, the point of attachment – where the tether meets the tool – and the anchor point – at the other end of the tether – have to survive shock loading. If not designed for these sudden forces, both attachment points and anchors can deform, break, or tear loose. When the worker is used as the anchor, shock can be transmitted to their body. In a worst case scenario, that falling object can be the initiator that pulls the worker down with it.

Keeping it Together: Tool Tethers

The tether ties this all together. Ideally, it will not only prevent the tool from hitting the ground, but also absorb some of the dynamic force, decelerating the tool to a smooth, safe, uneventful stop, reducing shock loads on the tool, the attachment point and the anchor. The same rationale that discourages bungee jumpers from using steel cables applies to smaller objects as well.

But a shock-absorbing tether has to be more than a bungee cord from the local home improvement center. Improvised tethers are a risky proposition, since they often rely on poorly constructed loops, connections, knots or other weak points. An engineered tether will be designed and independently tested in both static (hanging) and dynamic (falling) modes, including safety factors for each. Can it be “over-designed?” Sure. A tether designed to catch a falling Jeep would be pretty clumsy to use for an ordinary hammer.

Key selective criteria include the object weight and method(s) of attachment to the tool and anchor. Minimizing the length of the tether reduces the maximum time and distance that the tool can travel, and as a result, the acceleration and forces which must be absorbed. For example, a wrench on a 3-foot tether, held fully extended overhead, could drop a total of 6 feet (3 above the anchor point, plus 3 feet past the anchor point) before fall arrest starts. The same tool on a 2-foot tether has a maximum fall distance of 4 feet until deceleration begins.

Generally, anchoring tools to the worker is discouraged, unless relatively small and light. Even if the potential shock loads are limited, tools anchored to a worker can snag as he or she moves about. Railings, worker hoist buckets and other designated anchor points are usually a better choice.

As with personal fall arrest systems, components need to be selected appropriately and inspected regularly. Worn or damaged tethers and attachments need to be replaced. And anchors may need to be replaced or repaired. If a tether has sustained a severe fall, it has done its job, and should be replaced, even if there’s no obvious damage.

Formulas are Your Friend: Dropped Objects Prevention Scheme

Some people want hard numbers without the degree in physics. But even simple calculations get confusing, when mass technically isn’t weight and unfamiliar terms like “Newtons” and “Joules” get thrown around (feel like there is a missing point here). As an industry-wide initiative focused on preventing dropped objects, DROPS (Dropped Objects Prevention Scheme) has published some user-friendly charts, in both metric and imperial versions, along with a calculator that works in a spreadsheet. These plot the mass of a dropped object against the distance it falls, taking the pain and the exponents out of quantitative answers for the bean counters.

Vertical velocity may be fun during skydiving, but on the job, slow, controlled deceleration of worksite tools is preferable. Complex as the calculations can be, the concept itself is much like dropped forces: easy to absorb.

When you’re working at heights, dropped objects prevention is important not only for those working on the ground below – but for you as well. Because your tools should help you out – not drag you down.

With ever-increasing options for tool tethering inevitably they're going to be imitators to prove the pioneers of tool tethering are still the leaders. We're going to compare our scientifically engineered Squids Shock-Absorbing Tool Lanyards to a few popular imitators.

We'll use this drop stand and a load cell to measure the peak forces generated by dropping this three and a half pound pipe wrench. The greater the force registered the greater the risk to workers of being pulled down with their drop tool.

First, let's look at the forces generated by competitor lanyard. A generated 46.7 pounds of force.

Next, let's look at the forces generated by competitor b. This lanyard generated 71 pounds of force.

Finally, let's compare those results to the shock-absorbing design of Ergodyne Squids Tool Lanyards. The Squids Lanyard only generated a force of 18.1 pounds.

As you can see the choice is clear to protect yourself and those working below you. Accept no substitutes, choose Ergodyne Squids Tool Lanyards to tether your tools. For more information on Squids Tool Lanyards and dropped object prevention visit ergo.zone/drops.

Stay Tethered: Ergodyne Squids

Tethering tools to a secure anchor point is crucial to safety at heights and on jobsites. Ergodyne offers a comprehensive line of dropped object prevention, for all of your tool tethering needs. From retractable lanyards to bags and pouches, Ergodyne has a multitude of options for each and every person, environment and situation. Protect yourself, your peers and your tools - it can save lives.

FAQ

A tool lanyard is a safety device used to secure tools to a worker, harness, belt, or anchor attachment to prevent them from falling. It helps protect people and equipment below by reducing the risk of dropped object injuries and damage.