Is Your Lanyard Legit?: Five Must-Haves for Every Ansi-Compliant Tool Lanyard

44,000 workers were injured by dropped objects in 2017. 50,000 workers were injured in 2018. You don’t have to do the math to know we’ve got a problem on our hands.

ANSI/ISEA 121-2018 established minimum design, performance, labeling and testing requirements for solutions that prevent falling objects while working at height but, with incident numbers still trending up, it’s clear the mere creation of a standard isn’t enough.

As an industry, we must continue to not only raise awareness of the risk but also emphasize the importance of widespread adherence to ANSI/ISEA 121 as a way to mitigate it. With tool lanyards among the most integral and common equipment used to tether tools for prevention of dropped objects, ensuring ANSI-121 compliance on as many worksites as possible is a major step.

Five Must-Haves for Every ANSI-Compliant Tool Lanyard

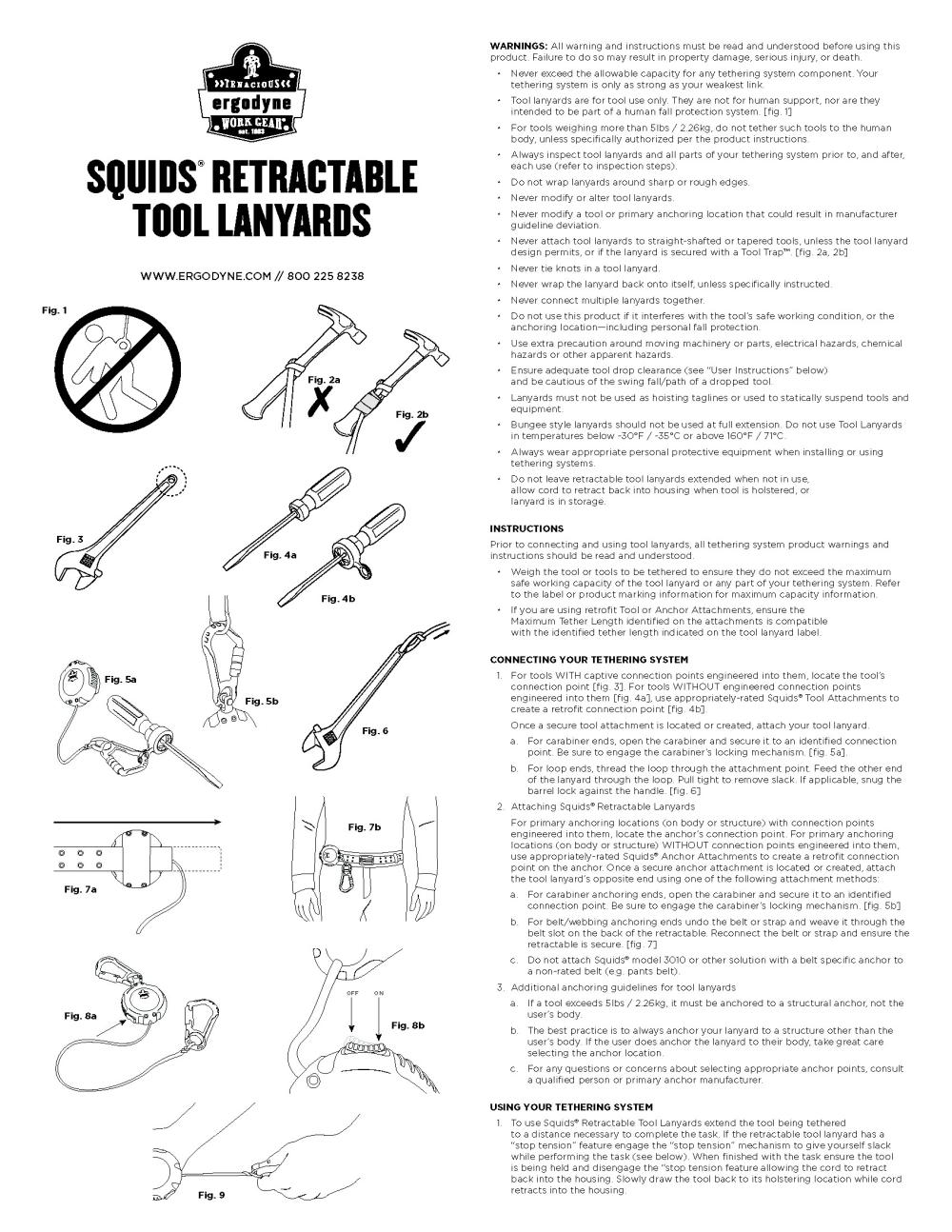

- Locking Carabiner Eye: Prevents tool from disconnecting during use

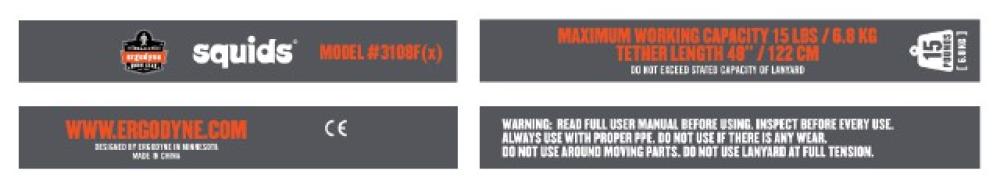

- 121 Marked Labeling: Clearly states required working lanyard information including: maximum weight rating, manufacturer information, warnings and lanyard length

- Product Instructions: Includes installation illustrations, as well as use, care and replacement guidelines

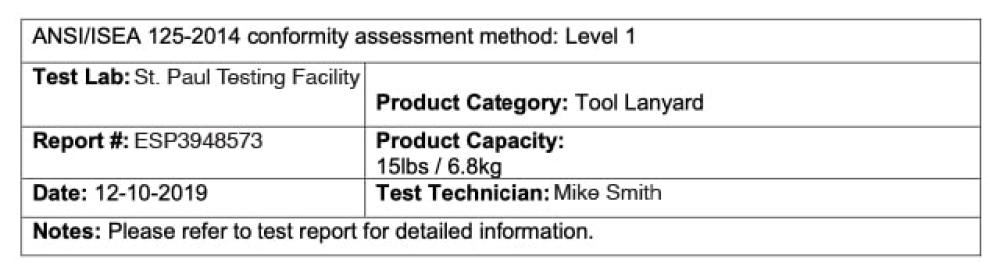

- COC: Certificate of Conformity: Identifies where and when ANSI/ISEA 121-2018 testing occurred