Understanding NFPA 70E and NFPA 2112 FR Standards - Dual Compliance

Professional stuntmen, race car drivers, Bruce Willis… and you? All major badasses, of course, but what these people all have in common is the fact that explosions are an inherent risk in their day job. And if you work in one of the industries where an arc flash or flash fire risk is present, you understand the need for the right protective equipment.

For workers whose jobs put them in the hot zone, flame-resistant (FR) clothing is one of the most important tools in their arsenal. Oil and gas, electricians, line workers, chemical plant workers and people in other similar industries are all at risk of coming into contact with an arc flash or flash fire hazard.

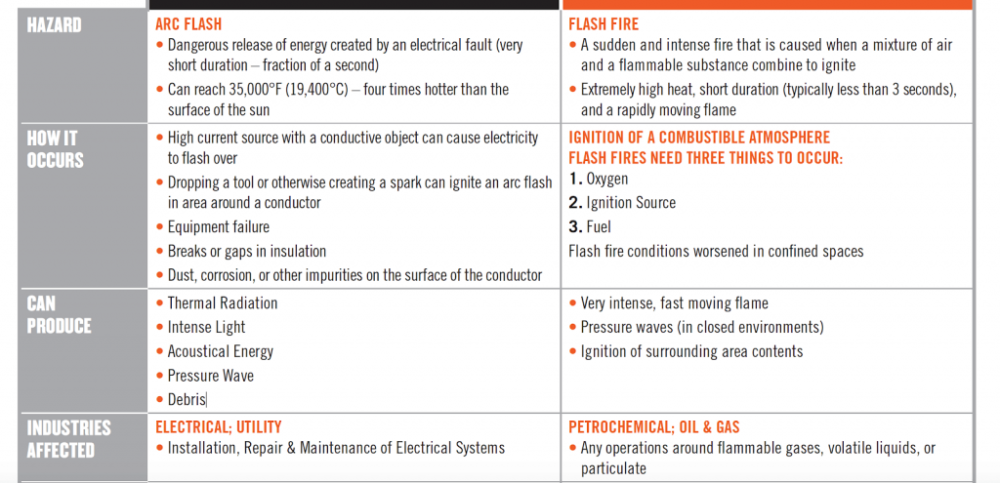

ARC FLASH VS. FLASH FIRE

Arc flash explosions are short, intense bursts of energy that can reach temperatures four times hotter than the surface of the sun (think 35,000°F), even though they only last for just a fraction of a second. A flash fire is a sudden, intense fire caused by ignition of a mixture of air and a dispersed flammable substance such as a solid, flammable or combustible liquid, or a flammable gas. It is characterized by high temperature, short duration, and a rapidly moving flame front.

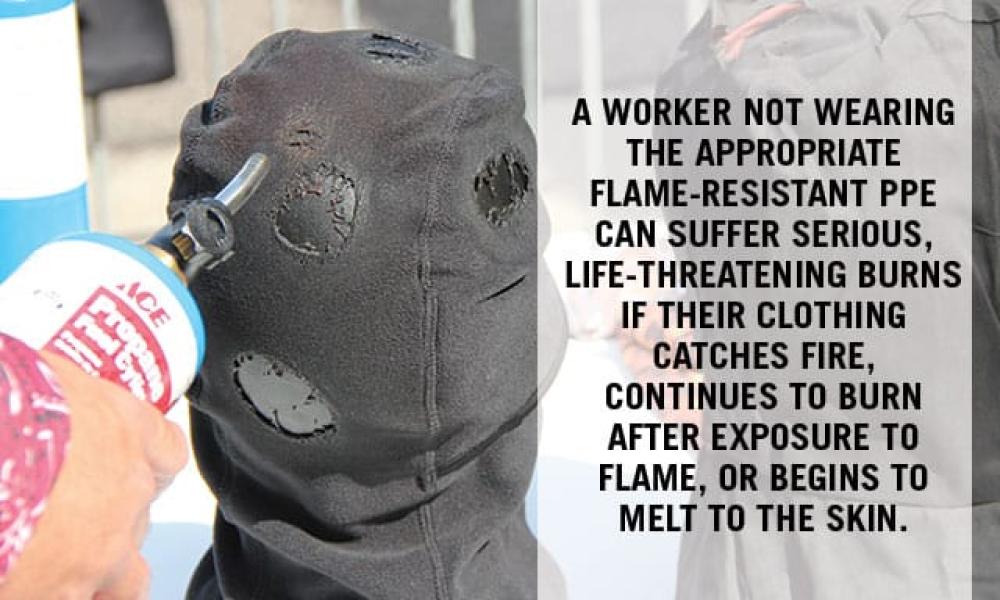

And it’s not just the initial burst that can be dangerous. Contrary to what you may have heard, among workers who have survived flash fires/explosions, the most severe burns are found on the areas that were covered by their regular (non-FR) clothing, and not on their uncovered head and hands, as most people believe. The burning clothing, in contact with the skin and continuing to burn long after the flame has retreated, causes the most severe burns. Clothing that melts without burning can also cause significant damage.

WHAT NOT TO WEAR WHEN FIRE HAZARDS ARE PRESENT

A worker not wearing the appropriate flame-resistant PPE can suffer serious, life-threatening burns if their clothing catches fire, continues to burn after exposure to flame, or begins to melt to the skin. Which is why OSHA “prohibits workers from wearing clothing that, in the presence of an arc, can potentially increase the extent of injury; that is, if the clothing would ignite and continue to burn, or if it melts on the skin. Thus, workers are generally prohibited from wearing clothing materials made entirely of, or blended with, synthetic materials such as acetate, nylon, polyester, or rayon.

OSHA goes on to say that “clothing made from 100% cotton or wool may be acceptable if its weight is appropriate for the flame and electric arc conditions to which a worker could be exposed. As heat levels increase, these materials will not melt, but they can ignite and continue to burn. The amount of heat required to ignite these materials is dependent upon a number of factors, including the weight, texture, weave, and color of the material.”

Material like untreated cotton has a very low ignition temperature of approximately 480°F (250°C) and burns intensely and rapidly. Untreated polyesters and nylons ignite easily 480° - 660°F (250°C - 350°C) and melt readily. Cotton/poly blends combine the worst qualities of both fabric in terms of ignition and melting. Remembering that an arc flash can reach temperatures of over 35,000°F (19,000°C), you can see how quickly and easily these various materials will ignite.

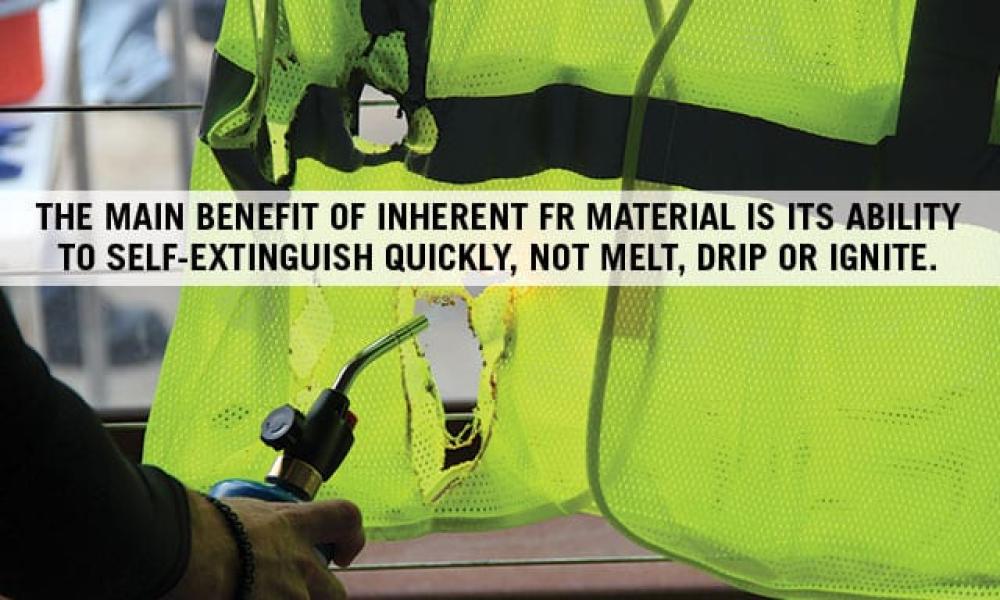

The main benefit of inherent FR material is its ability to self-extinguish quickly, not melt, drip or ignite. Because of this rapid self-extinguishing property, instead of suffering second or third degree burns from extended contact with fire, the worker may only suffer minor burns from the intense heat.

HOW SERIOUS ARE THE RISKS?

Each year, hundreds of burn injuries and deaths are recorded from workers encountering open flame and high heat or exposure to flash fires and electrical arc flashes without proper flame resistant personal protective equipment (PPE). In 2017, the U.S. Department of Labor Bureau of Labor Statistics reported approximately 123 worker fatalities and 3,120 injuries due to fire and explosions. And of these burn injuries, dozens experience severe burn injuries caused by the continued burning of their clothing. During the same year, nearly 15,400 workers sustained lost-time industries because of heat burns.

If the on the job risk can’t be eliminated, it is mission critical that the supplied or chosen workwear and PPE can withstand the heat and protect against the real risk of arc flash or flash fire hazards in the electrical/utilities or petrochemical industries. Employers are required by OSHA regulations to assess the risks in their workplace and select appropriate PPE, including clothing, that protects against identified hazards. But it’s also important for the individual workers to understand the standards and protect themselves.

THE HAZARDS, EXPLAINED

MIND THE FR STANDARDS

Every day, as many as 5 to 10 arc explosions occur from electric equipment. To mitigate these risks, regulatory bodies have created a number of standard test methods and specifications that discriminate amongst the different fabrics that are protective against flame and heat exposure, as well as specific types of industrial exposures.

Different standards are set in the industry to address a variety of applications where flame and heat resistant protective clothing may be needed. And there are a number of standards in regard to flame-resistant PPE but we’re going to focus on NFPA 70E and NFPA 2112. NFPA is the National Fire Protection Association and is “a global self-funded nonprofit organization, established in 1896, devoted to eliminating death, injury, property and economic loss due to fire, electrical and related hazards.” This group is widely known as a codes and standards organization, responsible for testing, researching and setting standards that “are designed to minimize the risk and effects of fire by establishing criteria for building, processing, design, service, and installation around the world.”

The two NFPA standards that we will define are NFPA 70E and NFPA 2112. In the marketplace today, you’ll find a variety of FR workwear that meets either one or the other standard, with a smaller percentage of gear meeting both standards.

NFPA 70E STANDARD

NFPA 70E, Standard for Electrical Safety in the Workplace, is published by NFPA and is an electrical safety standard aimed at companies that operate in the electrical utility industry and is generally directed towards end users. The purpose of this standard is to provide a "practical safeguarding of employees during activities such as the installation, operation, maintenance, and demolition of electric conductors, electric equipment, signaling and communications conductors."

In plain language, NFPA 70E was developed to protect electrical workers in all industries who work on or near energized parts or equipment that are capable of generating an arc flash, like high-voltage switching and grounding gear, panel boards, switchboards, motor control centers, motor starters, metal-clad switchgear, transformers, and meters. If you are an electrical maintenance worker, industrial electrician, or machine operator, you should look for clothing that is 70E rated.

A portion of the standard addresses safety-related work practices including gloves, sleeves, footwear, head protection, face and eye protection as well as protective apparel. A key part of the standard establishes CAT categories, formally hazard-risk categories (HRCs), which define the level of arc rating needed by clothing to perform specific hazardous tasks where the potential for an arc flash exists. The standard identifies a specific category for each type of work normally performed by electrical workers.

NFPA 2112 STANDARD

NFPA 2112, Standard on Flame-Resistant Clothing for Protection of Industrial Personnel Against Short-Duration Thermal Exposures from Fire provides criteria for clothing materials in terms of flash fire. The purpose of this standard is to “provide minimum requirements for the design, construction, evaluation, and certification of flame-resistant garments for use by industrial personnel, with the intent of providing a degree of protection to the wearer and reducing the severity of burn injuries resulting from accidental exposure to hydrocarbon flash fires.

This standard is for clothing used as protection against industrial flash fire hazard, typically seen in petrochemical and oil and gas industries. Flash fires are characterized as a sudden, intense fire which in short in duration but severe in potential danger. All flash fire clothing that is compliant with NFPA 2112 have to meet extremely stringent requirements and must to be tested and certified by a third party. The garment must defy melting, dripping or after-flame burning.

It must also achieve a 50% or less predicted body burn, which means that the garment will pass the test if it records less than 50% of a second- and third-degree body burn in a 3-second flash fire. These numbers were determined by looking at survival rates when humans suffer second- or third-degree burns over more than 50% of their body. Unlike the 70E which is expressed in calories, the 2112 data is expressed as a percent body burn, and the lower the number, the better the protection.

Note: NFPA 2112 does not apply to protective clothing for electrical flashes, technical rescue or any fire fighting operations or hazardous materials emergencies.

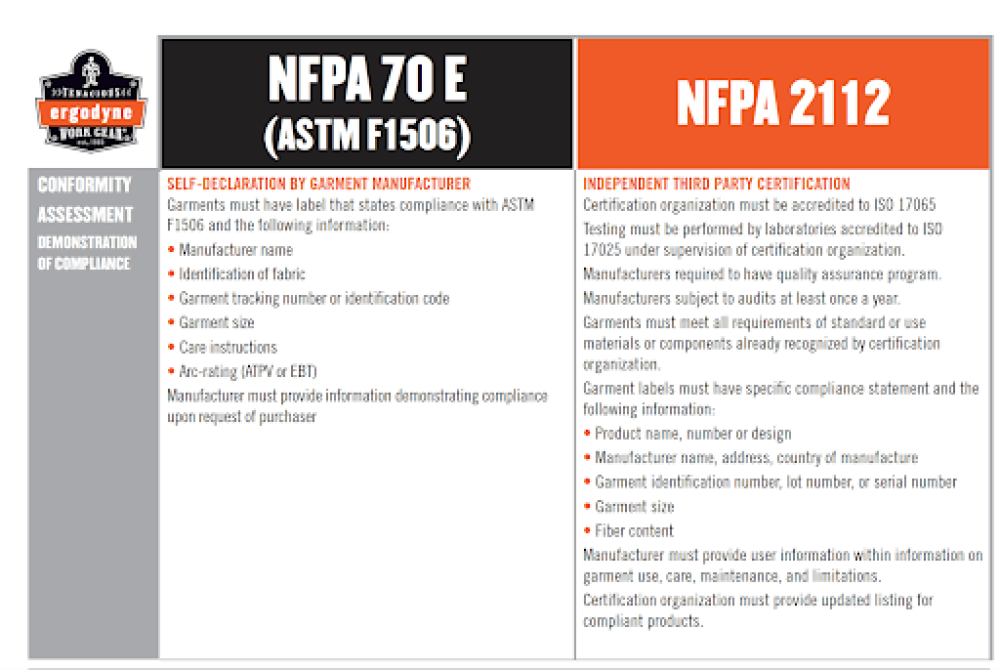

COMPLIANCE WITHIN FR STANDARDS

As we’ve discussed, NFPA 2112 is a clothing standard for protection against industrial flash fire hazard, and NFPA 70E is for clothing protecting against the thermal hazards of an electric arc. The hazards are somewhat similar but when selecting FR clothing, it’s important to recognize that compliance with one standard does not necessarily mean compliance with the other.

NFPA 2112 refers to compliance both within the fabric itself and the finished garment, and must be tested and certified by a third party. The requirements to be listed a 2112 certified garment are far more stringent, and if the garment passes, the manufacturers must label the product with the certification organization’s mark (think the Underwriters Laboratory stamp that you see on a number of household products in the marketplace). If you are purchasing a product that is NFPA 2112 certified, you can be assured that it is using compliant materials, and that the finished product is compliant as well.

The requirements for NFPA 70E are based solely on the fabric alone, and not necessarily the finished product. Furthermore, NFPA 70E is a self-declaration standard. This means that a manufacturer can test products themselves, either in-house or out-of-house, and declare themselves compliant and label products as such. However, the regulations for 70E say that the clothing must still be able to be worn following an arc event, so some manufacturers will test and certify the garment as a whole, but it is not required.

Key Tests

Below are the criteria each garment or fabric is tested in order to be certified to either standard. And in the graphic below, you’ll see the requirements for each garment to prove that it has been tested and certified.

70E Tests

- ASTM D7138 (thread melting resistance): Thread used in garments must be of flame-resistant fiber and not melt at 500F

- ASTM D6413 (vertical flame resistance): When exposed to flame for 12 seconds, garment fabrics must:

- Self-extinguish (after flame) in 2 seconds or less

- Exhibit damage (char length) of 6 inches or less

- No melting or dripping can occur

- Fabric must meet these standards after 25 wash and dry cycles

- ASTM F1959 – Arc Testing: determines how much heat a certain fabric will block from an electric arc BEFORE the onset of second degree burns for the wearer (ATPV or EBT values reported in cal/cm2)

2112 Tests

- ASTM D7138 (thread melting resistance): Thread used in garments must be of flame-resistant fiber and not melt at 500F

- ASTM D6413 (vertical flame resistance): When exposed to flame for 12 seconds, garment fabrics must:

- Self-extinguish (after flame) in 2 seconds or less

- Exhibit damage (char length) of 4 inches or less

- No melting or dripping can occur

- Fabric must meet these standards after 100 industrial laundering cycles

- ASTM F2894 (heat resistance): When exposed to 500F for 5 minutes, garment fabrics must:

- Not ignite, melt, drip, or separate

- Not shrink more than 10%

- ASTM F2700 (heat transfer performance): When exposed to combined convective and radiant heat at 2.0 cal/cm2/sec, garment fabrics must have a HTP rating of 3.0 cal/cm2 or greater (contact) and 6.0 cal/cm2 or greater (spaced)

- ASTM F1930 (instrument manikin test): under simulated flash fire condition, predicted 2nd and 3rd degree total body injury is no more than 50% of total body surface area covered by sensors (less head, hands, and feet)

- Label Print Durability Test: garment labels must remain legible and in place after 100 industrial laundering cycles

READ THE FR LABELS

Unfortunately, despite the existence and promotion for using standards to qualify clothing in the workplace, often there is still incorrect information provided to end users. Some tests are used to represent products as flame resistant or protective in ways that are outside the scope of their intended use and may, in some cases, be a complete misrepresentation of the product’s protective capabilities. When looking at FR products, there are two common examples that may be listed but these do not ensure compliance with NFPA 70E for arc flash and 2112 for flash fire hazards.

Two common examples include:

- Some manufacturers infer that clothing meeting the Consumer Product Safety Commission requirements in Title 16, CFR 1610 (Standard for Flammability of Clothing Textiles) is protective against flame exposure. This regulation applies to ALL clothing sold in the United States and simply helps organize textiles into classes based on how quickly they burn. Textiles that have a flame spread between 3.5 - 7 seconds are considered normal flammability and are acceptable for use in clothing. Standards noted above only allow for a 2 second maximum after flame. And when every second means precious escape time for a worker, which standard do you want your FR workwear to pass? Limits are set to exclude unreasonably dangerous fabrics from being used in the general U.S. clothing industry.

- Other manufacturers may cite an incorrect standard, such as NFPA 701 (Standard Methods of Fire Tests for Flame Propagation of Textiles and Films) or NFPA 702 (Standard on Flammability of Wearing Apparel), to base claims of their product’s flame resistance characteristics. NFPA 701 clearly is intended to address home and industrial furnishings such as draperies and wall coverings. NFPA 702 was withdrawn in 1986 and was never intended to cover protective clothing applications. It also has several other standards that provide requirements for specific types of flame and heat resistant clothing.

It is always best to check with the manufacturer to see what claims are being made and, if there is a question, to ask for documentation that demonstrates the claim of a particular product meeting a standard or specification. The product label should clearly state all standard compliances.

REMEMBER THIS

When exposed to flame or high heat, ordinary clothing can quickly ignite, burn or degrade causing serious burn injury and potentially, death. For those applications where exposure may occur, it is critical that workers are provided with and correctly wear proper flame resistant PPE.

Ergodyne offers a robust line of fire resistant PPE that protects all workers, especially those exposed to high heat and flames on a regular basis. And when every fraction of a second counts, you want to be sure that you and your workers are covered with the best possible equipment available.

DOWNLOAD THE COMPLETE COMPARISON CHART EXPLAINING BOTH STANDARDS HERE >>>

FAQ

NFPA (National Fire Protection Association) standards become enforceable when adopted by regulatory agencies like OSHA or referenced in company policies or contracts. Compliance may also be required to meet industry best practices or insurance requirements.

CAT 2 (Category 2) FR clothing refers to garments that provide a minimum arc rating of 8 cal/cm², offering protection against moderate arc flash or flash fire hazards. It’s part of the PPE Category system defined by NFPA 70E, used primarily in electrical safety.

FR stands for Flame Resistant. FR clothing is designed to self-extinguish after exposure to flame, reducing the risk of burn injuries by not continuing to burn or melt onto the skin.

Flame-resistant clothing should be worn whenever there is a risk of exposure to flash fire, arc flash, or other thermal hazards. This includes industries such as oil and gas, electrical utilities, welding, and chemical manufacturing, based on hazard assessments and regulatory requirements.

A material’s chemical composition and structure determine whether it melts or burns. Thermoplastic fibers (like polyester) tend to melt, while thermoset fibers (like aramids) tend to char and resist ignition. The presence of flame-retardant treatments or other inherent FR properties also influences how the material reacts to heat.