Understanding the Temperature Ratings of Your Cold Storage Thermal Gear

Thermal performance is like a hipster’s coffee order—complex. Sure, your gear might be rated for -50°F, but how active will you be? And for how long? Did you have a few beers last night? How old are you? Did you eat a good breakfast? And how about... (One triple venti half-soy non-fat decaf organic chocolate brownie iced vanilla double-shot gingerbread latte coming right up!)

The truth is, thermal ratings are a performance guide, not gospel—the best direction available through exhaustive testing and consideration of three major factors…

- CLO Value

- Activity Level

- Time in the Cold

Add to those three factors a nearly endless list of personal and environmental variables and you have a maddeningly wide performance variance and the making of a customer service nightmare for anyone in the business of keeping cold storage workers warm, safe and productive with thermal gear (“…but you said this was rated to…”).

INSULATION + ACTIVITY + TIME = YOUR COMFORT EQUATION

Insulation: CLO Value

CLO is a unit of thermal resistance for measuring the insulating ability of the material. One CLO is equal to the amount of insulation that allows a person to rest comfortably at 70°F (21°C) in a normally ventilated room. Higher CLO means more thermal insulation.

CLO values are calculated based on several factors, including the type and thickness of the material. They are tested in controlled environments, often using thermal manikins equipped with sensors that simulate human heat production and sweat patterns or something called a guarded hot plate which measures the heat transfer from a hot plate through the sample into a cold environment in accordance with the ASTM F1868-14 Standard Test Method for Thermal and Evaporative Resistance of Clothing Materials Using a Sweating Hot Plate (rolls right off the tongue, don’t it?). If you were the extra credit kinda kid in school, you can nerd out on all the details of the standard and testing methods on the ASTM website.

Activity: MET Level

The next variable in your comfort equation is MET (Metabolic Equivalent of Task) Level. That’s defined as the ratio of your working metabolic rate relative to your resting metabolic rate. Metabolic rate is the rate of energy expended per unit of time. It’s one way to describe the intensity of an exercise or activity. MET Levels are categorized as Light, Moderate and Vigorous.

- Light < 3 METs (Forklift driver, equipment operator, job foreman)

- Moderate 3-6 METs (Picking & packing, delivery, baggage handlers)

- Vigorous > 6 METs (Concrete work, oil and gas, tower climber)

Time: Duration in the Cold

And finally, we have time. In this instance, time means the duration you’re in the cold before breaks or removal, not the accumulative time you’re in the cold for your shift.

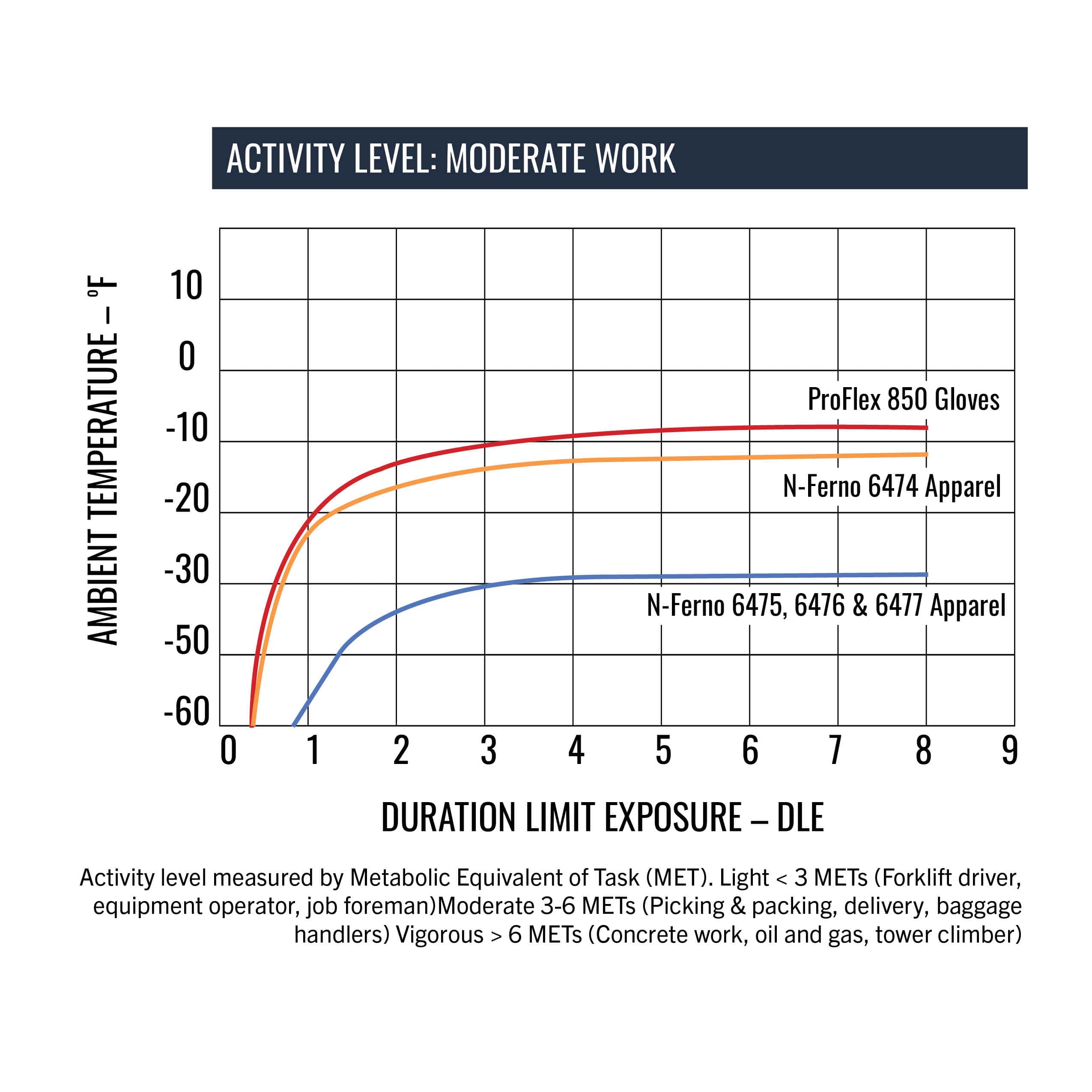

As you can see in the chart below, the longer your duration, the lower the return on thermal performance.

[VIDEO] Understanding the Temperature Ratings of Your Thermal Gear

Al:

We're here in a cold storage facility to unpack temperature ratings in thermal gear. Okay, so what goes into a temperature rating? Well, it's really an equation of three variables, right? You have your insulation, which is measured by something called CLO. You have your activity levels, which is measured by something called MET Activity Level.

And then you have the time factor. That's how much time you are out in the cold, right? So you put insulation plus activity level plus time and that equals your temperature rating. So when we're talking about CLO, again, that is really measuring the effectiveness of your insulation and how warm it is. Very simple math there, the higher the CLO, the warmer the insulation.

Okay, so one CLO is equal to the amount of insulation that allows a person to rest comfortably at 70 degrees Fahrenheit. For context, your typical flannel shirt measures about 0.30 CLO, while the average down jacket measures about 0.55 CLO. Cold storage gear like Ergodyne’s new freezer jacket and bibs features a toasty 2.59 CLO. So CLO values are tested and determined in controlled environments, right?

So they're using thermal mannequins equipped with sensors that actually simulate human heat production and sweat patterns. Now, when it comes to activity level, that is measured again by something called MET Activity Level, and you can either be light, moderate or high, very active. MET stands for Metabolic Equivalent of Task that's defined as the ratio of your working metabolic rate relative to your resting metabolic rate.

It's really one way to describe the intensity of an exercise or activity. So again, MET levels are classified as either light, moderate or vigorous. So on the light end, that's measuring less than 3 METs and that would include jobs like forklift drivers or, say, equipment operator. The moderate MET levels are measured between three and six METS. On the moderate side you would have your pickers and packers and maybe delivery folks. And then on the vigorous side of things, which is more than six METs, you have people doing high activity work, right? So think about concrete demo or tower climbers. And then the third variable is, of course, how much time you are in the cold and exposed to the cold.

The longer you're in the cold, your temperature rating is going to dip. Okay, so there you have it, Insulation plus activity, plus time put them all together and you've got your comfort equation, right? Good basis for temperature ratings, but it's not that easy. There's a whole host of other variables that go into affecting the thermal performance of any sort of garment.

And to sort of help parse out those variables, we brought in our expert, Claudia Weber. She is part of the Ergodyne Innovation Team charged with designing and testing our thermal work gear. Welcome, Claudia.

Claudia:

Hi. Thanks for having me.

Al:

It's a pleasure to have you. So why isn't it that easy, right? If something is rated to -50, why can't we just bank on that?

Claudia:

Yeah, because everybody is a little bit different. You and I could go into the same cold storage environment wearing the same gear, and we're two different people, and we might feel a different sensation when we're in there. So there's a few factors that I like to think about. One is, how old are you? So somebody who is older is actually more at risk for having a cold related illness.

Somebody who is overweight is also actually at a higher risk. Something to think about. If you have a medical condition. So just giving an example, Hypothyroidism, diabetes, sometimes those types of medical conditions can actually lower your circulation rate. And so in turn, you might have a harder time staying warm in the same exact environment that another person would be in.

Another thing to think about is hydration levels. So it's so easy in the summer when it's hot to be chugging water, but when it's cold or you're working in a cold storage environment, you might not be drinking enough water. Our body actually kind of fakes us out and tells us that we don't need as much when we get cold because all the blood vessels are kind of getting thinner towards the extremities of our body and the blood is rushing to the core of your system.

So it's protecting your heart, your lungs, your brain. So sometimes back to what I'm saying is we often don't think that we need water when we do. So that's important to think about.

Al:

So a lot of different physical factors. One example that that comes up a lot is like sleeping bags. Right? Sleeping bags are like, well, those are rated to -30 Fahrenheit, and, you know, that is a pretty stable rating. People can count on that. But there are a bunch of environmental factors too that go into thermal ratings, right?

Whereas if you're in a sleeping bag, you're likely in a tent. You're not moving around. There's not any wind. What can you tell us about maybe some environmental factors that are mixed in with those physical factors you were just talking about?

Claudia:

Yeah. So I think the environmental factors are a bit more obvious. So if you're working in damp air, if there's a lot of wind. So I never thought there would be wind in a cold storage environment, but they have those stands running. It is cold. And then you stand in front of the wind and it's even colder.

So that's a big factor. Of course, just the temperature that you know, that it's set to if you're outside or inside. Those are some big ones. If you're also working on machinery, that is cold itself. So metal, think of that. Those are just some environmental factors. So you kind of need to combine the personal as well as the environmental.

When considering, how is it going to affect you as a person?

Al:

Yeah, absolutely. That makes a lot of sense.

Claudia:

And I don't want to forget too. Also, if you don't get enough sleep or you're drinking, you're boozing hard the night before you took drugs, that can definitely affect how you feel the next day as well.

Al:

Okay. All right. So then, all that in mind, what advice would you give to workers that are looking for the proper thermal gear to wear?

Claudia:

So a few things that I personally would look for is you want to look at the temperature rating. We have it there for a reason, but it is a guideline, it is a benchmark. It is not the end all be all for every single person. So look at it. See if it fits in the environment that you're working in.

Two is use this garment and try to test it, bring it to your facility, see if it works for you. Every facility is a little bit different and every person is different as well as don't use this garment as the only garment you're wearing. You are wearing something underneath it. So consider layering wear your base layer, your mid-layer, wear insulated boots, etc. maybe wear the hand warmers if you know your fingers get colder during the day or wear foot warmers if your feet naturally get colder.

I also would make sure you're wearing properly fitted PPE. So let's say you're the last worker. You grab the jacket and it's three sizes too big. Well, it's going to be baggy. You're going to get a ton of wind and air going through your garment. And in turn, you're probably going to be colder than the rest of the workers.

So make sure it fits properly.

Al:

All right. I think that's some pretty good advice for the folks out there. Once again, I want to thank you all for watching. Listening. If you're listening to this on Spotify or Apple, please do remember that you can catch a video version of this on YouTube or ergodyne.com. Thanks again, everybody, for watching, listening and stay safe out there people.

Temperature Ratings: The Ergodyne Way

We’ve developed a straightforward, no-BS system to help you choose the right warming gear for your environment by sorting our apparel into three temperature-specific categories: warm, warmer, and warmest. Each bucket reflects a specific range of real-world conditions, so you can easily match your gear to the job, the weather and how long you’ll be out in it.

WARM: rated for above 0°F. Perfect for moderate cold, active work and those in-and-out-of-the-elements kind of days.

WARMER: rated for 0°F to -19°F. This tier offers dependable insulation when you're up against extended exposure and frigid temps.

WARMEST: rated for -20°F to -60°F. These clothes are for the brutal, bone-chilling extremes in environments like cold storage and outdoor work in freezing temperatures.

Our goal? Temp-rated confidence in the cold no matter how you define it.

PERSONAL FACTORS THAT CAN AFFECT THERMAL PERFORMANCE

Insulation, activity and time. Put it all together and you get a strong reference point for claiming temperature ratings. But oh, if it were only so simple, friends. Just when you think you’ve got it all figured out, a whole host of personal factors come into play to make things interesting.

There are some we can’t do much about, such as age (wish we could). Others are more up to us, like maintaining an appropriate body weight, ensuring proper hydration, steering clear of drugs and alcohol and getting adequate sleep.

Acclimatization is another biggie. This involves progressively increasing time spent in cold environments. Workers can foster a gradual adaptation to the cold by taking regular breaks to warm up and slowly building their body's resistance to the chilly conditions.

It all comes into play to turn what could be a fairly straightforward rating system into a highly subjective one. A glove that works just fine in -10°F for one person might not do the trick for the other.

COLD STORAGE FACILITIES: ENSURING SAFETY WITH THE RIGHT PPE

Cold storage facilities are complex environments, each with different temperature zones to accommodate various products:

- Deep Freezer Areas: These are designed for frozen goods like meat and ice cream, with temperatures ranging from 5°F to -20°F. Workers need specialized PPE such as freezer warehouse clothing to safely operate in these frigid conditions.

- Chiller Rooms: Maintained at around 35°F, these rooms are for items like vegetables and fruits. PPE requirements here are less stringent as freezer gloves might not be necessary due to the milder temperatures.

- Ambient Zones: These are areas within the cold storage facility that are kept at temperatures comfortable for general human occupancy. These spaces do not require specialized cold storage clothing.

Occupational Safety and Health Administration (OSHA) regulations stipulate that employees working in cold environments must be protected. This means equipping them with proper cold storage clothing and other gear.

- Base Layer: When the goal is to stay warm, productive and agile, a moisture-wicking, quick-drying layer is key. Moisture is your enemy.

- Insulated Jackets, Bibs, Coveralls: Look for garments tested to and appropriate for the environment you'll be working in.

- Thermal Gloves: Essential to protect against frostbite and maintain dexterity in chillers and freezers.

- Footwear: Adding foot warmers + traction devices might be the boost tootsies need to stay warm and firmly planted on the ground (slips, trips and falls wreak havoc on the job).

- Thermal Headwear: In addition to fingers and toes, the body parts most susceptible to frostbite are above the neck (because they’re often left exposed).

Of course the end game for all the above is preventing cold-related illnesses and injuries. This toolbox talk will help you get up to speed on the most common of them, including frostbite.

CHOOSE THE RIGHT COLD STORAGE GEAR

Ergodyne's Cold Storage Collection is designed, built and tested with workers at some of the biggest cold storage facilities on the planet to ensure maximum warmth, comfort and durability when you work in the realm of eternal winter.

See Cold Storage Collection >>>

FAQ

A CLO rating, or clothing insulation value, is a unit of measurement that describes the thermal insulation provided by an article of clothing. A CLO value of 1 is equal to the amount of clothing required by a resting human to maintain thermal comfort at a room temperature of 70° Fahrenheit (21° Celsius). Higher CLO values indicate greater insulation, while lower CLO values indicate less insulation.

It can be tricky to determine how warm one needs to dress when planning on facing the cold. Here is the equation we like to follow when it comes to selecting the most comfortable gear in cold conditions: Insulation + Activity + Time = Optimal Comfort. CLO is a unit of thermal resistance that measures the insulating ability of clothing. It is calculated based on the type and thickness of the insulation material. MET is a measure of the intensity of an activity, and is categorized as light, moderate, or vigorous. The final variable in the comfort equation is time, which refers to the duration of exposure to cold. There are also other factors that should be considered, like age, sex, body fat, medical conditions, circulation, weather and/or personal preference.

Several factors affect a CLO rating, including:

- Insulation: Insulation is a key variable in cold weather gear. The type of insulation and the grams of insulation are major factors that determine the warmth felt when wearing a garment. Many competitors use a poly fill insulation, which requires higher grams of insulation to keep you warm, and therefore feels bulkier. Thinsulate is lighter and traps more air which keeps the wearer warmer. Thinsulate also launders better and keeps the insulation more compact yielding longer thermal retention. Other factors, such as the construction of the garment and the fit of the garment, can also affect how warm it is.

- Layering: Layering multiple garments can significantly increase the overall CLO rating of an outfit. It's always a smart idea when working in cold conditions to wear a base layer, mid-layer, and outer layer.

- Thickness of fabric: Thicker fabrics generally have higher CLO ratings than thinner fabrics.

- Air pockets: Air pockets trapped in a fabric's fibers provide insulation, so fabrics with more air pockets generally have higher CLO ratings.

- Fit: Properly fitted clothing traps more body heat, so well-fitting garments generally have higher CLO ratings than loose-fitting garments.

A chiller room, commonly referred to as a walk-in fridge, is a refrigerated space that is maintained at temperatures between 32 and 40° Fahrenheit (0 and 5° Celsius), but is usually held around 35° F. Chiller rooms are typically used to store fresh produce, dairy products, and other perishable goods that require refrigeration but do not need to be frozen.

A freezer is a refrigerated space that is maintained at temperatures below freezing, usually between 5 and -20° Fahrenheit. Freezers are typically used to store frozen foods, such as meat, poultry, and seafood.